Maintenance-Free

The U-Disc coupling offers the power density, large bore capacity, and high-speed capabilities of a metallic coupling. The U-Disc coupling also eliminates the need for maintenance, as with the elastomeric couplings.

Traditional gear and grid style couplings require additional grease multiple times per year to lubricate gear teeth and looping segments.

However, the U-Disc coupling does not have relative movement between mating parts, which allows for increased maintenance productivity and reduced unplanned downtime.

Additionally, by not having any moving components, the U-Disc coupling is torsionally rigid, prevents backlash, and is perfect for applications needing precise positioning – such as paper machines.

Power Dense

Even when comparing the U-Disc coupling with an elastomeric design, the customer must sacrifice space, since the maintenance-free elastomeric option would be much larger to handle the required horsepower and torque.

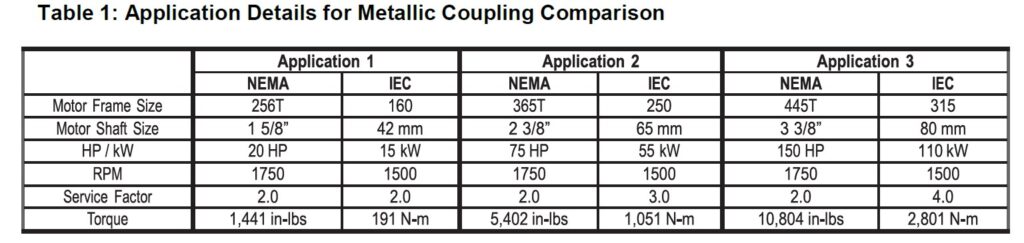

Table 1 lists three common application examples, driven by NEMA and IEC motors.

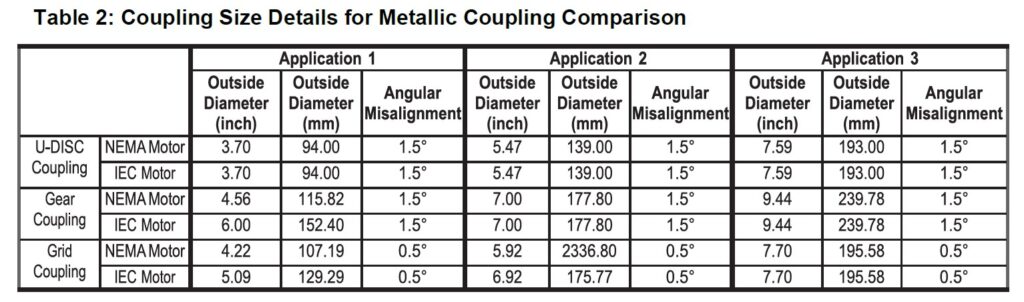

Table 2 reveals that the U-Disc coupling section has a smaller outside diameter than the grid and gear couplings.

The U-Disc coupling selection has equal angular misalignment to the gear coupling and more than that compared to the grid coupling. It is truly a power dense, maintenance-free coupling that has infinite life when properly sized and aligned.