U-Disc Geometry

The U-Disc coupling utilizes the newest generation of disc geometry – the dual-scalloped design – which offers an even distribution of material along the axis of bolt center.

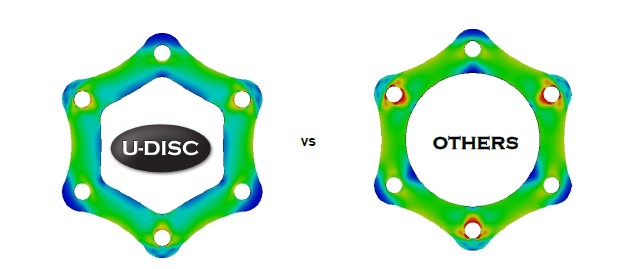

Using FEA (Finite Element Analysis), Figure 2 allows visibility of the number of high-stress areas within the disc to be limited to only a small area around the bolt hole.

The improved dual-scalloped design geometry delivers 13% less peak stress than competitor’s designs. This results in an average of DOUBLE the torque capacity.

The even distribution of material along the axis of bolt center maximizes the ability of the U-Disc to handle misalignment and offers three times the misalignment capacity of competitors.

Industry-leading torque ratings and misalignment capabilities lead to longer life, improved reliability, and reduced downtime through the U-Disc.

Unitized Factory Pre-Assembled Design

The U-Disc coupling spacer center assemblies include a spacer, two disc packs, and two guard rings.

The coupling spacer center assemblies are pre-assembled at the factory to ensure that the system is assembled with the required tolerances and torque settings.

It also allows simplicity when ordering spare parts. The customer may order a single part number and receive a single unit – guaranteed to have the precise tolerances every time!

The factory-assembled, unitized center assembly prevents any single component from transmitting the torque alone. Competitive designs ship loose discs for the end user to assemble. This increases the risk of proper installation, which can reduce the life of the coupling.

The unitized, factory-assembled drop-in spacer assembly is just another reason how the U-Disc coupling offers higher torque ratings, increased misalignment capacity, and infinite life!*

*when properly sized and aligned.